gob led display

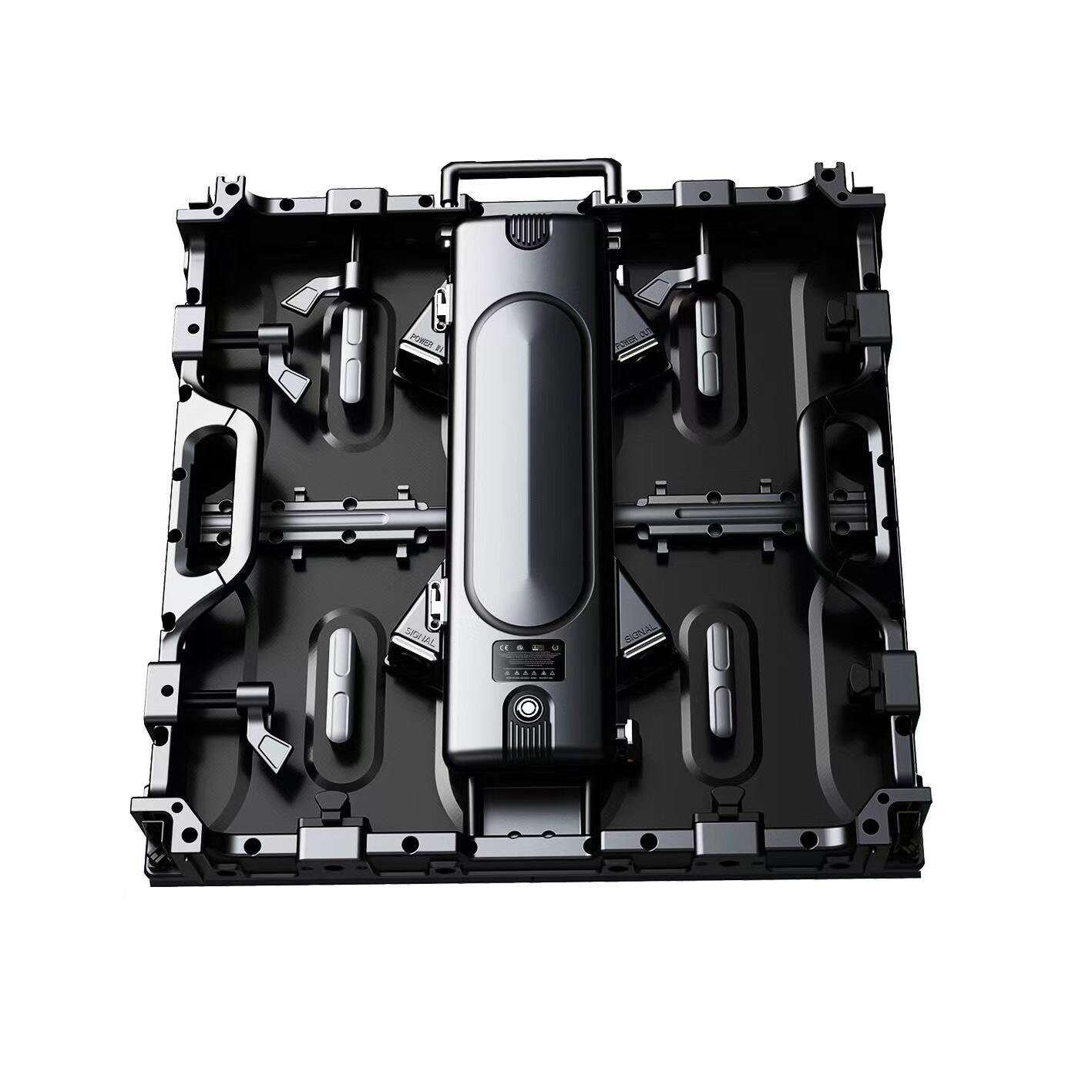

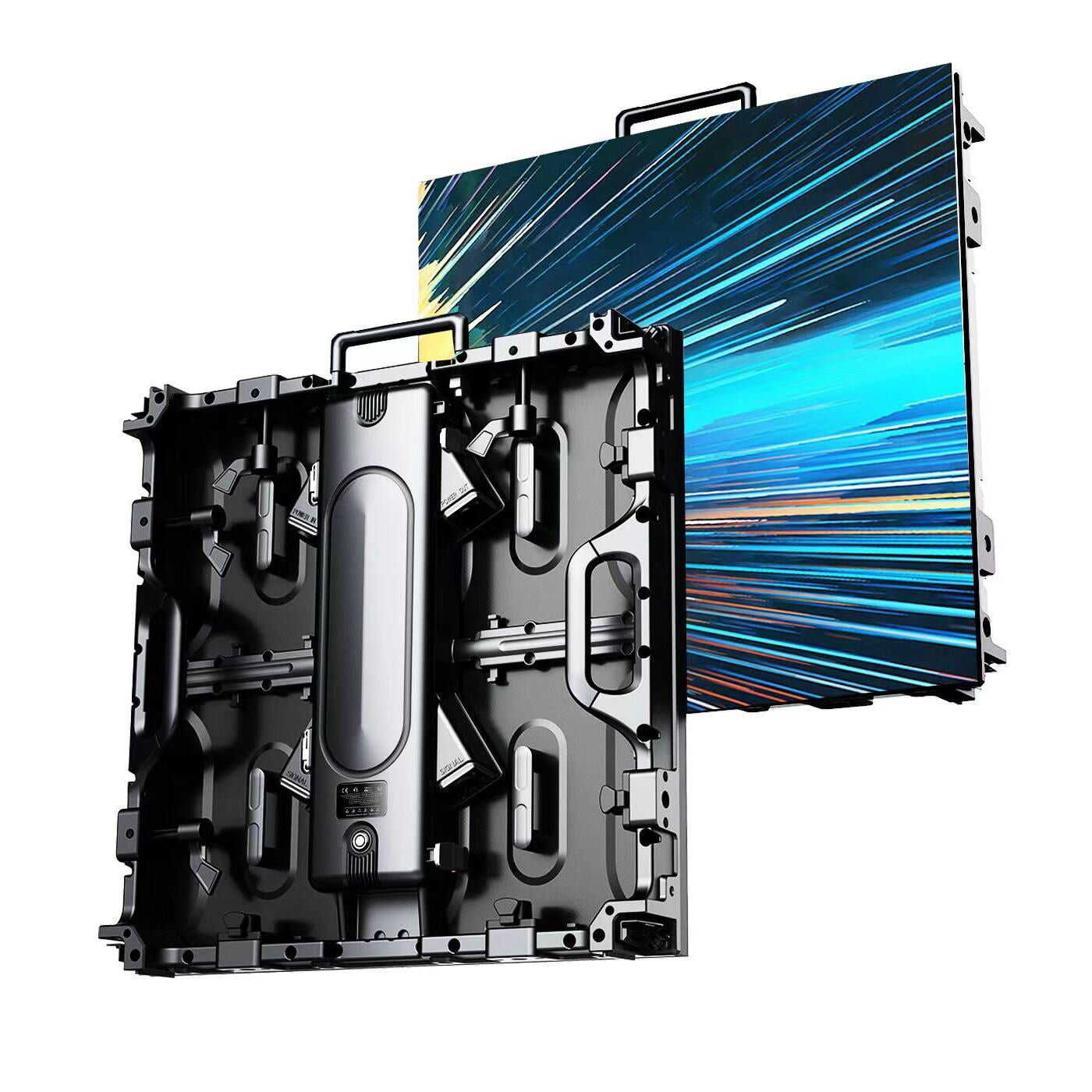

A GOB LED display represents a groundbreaking advancement in display technology, integrating Glass Optical Bonding (GOB) with LED components to create seamless, durable visual solutions. This innovative technology bonds the LED modules directly to a protective glass surface, eliminating air gaps and creating a unified display structure. The process involves precision engineering where specialized optical adhesives permanently connect the LED panel to the cover glass, resulting in enhanced visual performance and structural integrity. The display offers exceptional brightness levels, typically ranging from 800 to 1,200 nits, making content clearly visible even in bright ambient conditions. With a typical contrast ratio of 3000:1 or higher, these displays deliver deep blacks and vibrant colors across their entire viewing surface. The GOB technology also provides IP65 protection rating, ensuring resistance against dust and water ingress. These displays excel in various applications, from outdoor advertising and retail signage to control room monitoring and transportation information systems. The seamless integration of components results in minimal light reflection and improved optical clarity, while the protective glass layer adds durability without compromising display quality. Modern GOB LED displays typically feature refresh rates of 3840Hz or higher, ensuring smooth motion rendering and eliminating visible flicker.